|

N.C. GAS SOLENOID VALVES WITH MANUAL

RE-SET

|

|

|

Path - First page - Products - Gas Solenoid Valves & Accessories - GCR |

||

APPLICATION

Without power they are closed; they have to be re-opened manually and remain open when powered. Approved Class A Group 2.

For replacement coils please click here.

FEATURES

-

Constructed to EN standards; Aluminium body.

-

Linkage : DN 15 to 50 : screwed female EN 10226 ; DN 65 to 300 : flanged PN16 ISO 7005

-

Protection : IP 65.

-

Working temperature : –15...+ 60°C

-

Mounted with coil axis within 90° of vertical

| Power supply | Flow rate m3/h (2) | |||||||

| Code | DN | V | VA | P.max (1) mbar | 0.5 mbar | 1 mbar | Data sheet | |

| SCREWED | ||||||||

| GCR 815 | 1/2" | 230 V ~ | 9 | 500 | 5 | 7 | G 923 | |

| GCR 415 | 1/2" | 24 V ~ | 8 | 500 | 5 | 7 | ||

| GCR 215 | 1/2" | 12 V – | 8 | 500 | 5 | 7 | ||

| GCR 820 | 3/4" | 230 V ~ | 9 | 500 | 6.5 | 8.7 | G 923 | |

| GCR 420 | 3/4" | 24 V ~ | 8 | 500 | 6.5 | 8.7 | ||

| GCR 220 | 3/4" | 12 V – | 8 | 500 | 6.5 | 8.7 | ||

| GCR 825 | 1" | 230 V ~ | 9 | 560 | 8.7 | 11 | G 923 | |

| GCR 425 | 1" | 24 V ~ | 8 | 500 | 8.7 | 11 | ||

| GCR 225 | 1" | 12 V – | 8 | 500 | 8.7 | 11 | ||

| GCR 832 | 1"1/4 | 230 V ~ | 9 | 500 | 16 | 23 | G 923 | |

| GCR 432 | 1"1/4 | 24 V ~ | 8 | 500 | 16 | 23 | ||

| GCR 232 | 1"1/4 | 12 V – | 8 | 500 | 16 | 23 | ||

| GCR 840 | 1"1/2 | 230 V ~ | 9 | 500 | 20 | 27 | G 923 | |

| GCR 440 | 1"1/2 | 24 V ~ | 8 | 500 | 20 | 27 | ||

| GCR 240 | 1"1/2 | 12 V – | 8 | 500 | 20 | 27 | ||

| GCR 850 | 2" | 230 V ~ | 9 | 500 | 27 | 38 | G 923 | |

| GCR 450 | 2" | 24 V ~ | 8 | 500 | 27 | 38 | ||

| GCR 250 | 2" | 12 V – | 8 | 500 | 27 | 38 | ||

| FLANGED | ||||||||

| GCR 865 | 65 | 230 V ~ | 18 | 500 | 54 | 80 | G 923 | |

| GCR 465 | 65 | 24 V ~ | 20 | 500 | 54 | 80 | ||

| GCR 265 | 65 | 12 V – | 18 | 500 | 54 | 80 | ||

| GCR 880 | 80 | 230 V ~ | 18 | 500 | 54 | 80 | G 923 | |

| GCR 480 | 80 | 24 V ~ | 20 | 500 | 54 | 80 | ||

| GCR 280 | 80 | 12 V – | 18 | 500 | 54 | 80 | ||

| GCR 8100 | 100 | 230 V ~ | 18 | 500 | 93 | 140 | G 923 | |

| GCR 4100 | 100 | 24 V ~ | 20 | 500 | 93 | 140 | ||

| GCR 2100 | 100 | 12 V – | 18 | 500 | 93 | 140 | ||

| GCR 8125 | 125 | 230 V ~ | 18 | 500 | 180 | 260 | G 923 | |

| GCR 4125 | 125 | 24 V ~ | 20 | 500 | 180 | 260 | ||

| GCR 2125 | 125 | 12 V – | 18 | 500 | 180 | 260 | ||

| GCR 8150 | 150 | 230 V ~ | 18 | 500 | 180 | 260 | G 923 | |

| GCR 4150 | 150 | 24 V ~ | 20 | 500 | 180 | 260 | ||

| GCR 2150 | 150 | 12 V ~ | 18 | 500 | 180 | 260 | ||

| GCR 8200 | 200 | 230 V ~ | 18 | 500 | 350 | 510 | G 923 | |

| GCR 4200 | 200 | 24 V ~ | 20 | 500 | 350 | 510 | ||

| GCR 2200 | 200 | 12 V ~ | 18 | 500 | 350 | 510 | ||

| GCR 8300 | 300 | 230 V ~ | 18 | 500 | 800 | 1,200 | G 923 | |

| GCR 4300 | 300 | 24 V ~ | 20 | 500 | 800 | 1,200 | ||

| GCR 2300 | 300 | 12 V ~ | 18 | 500 | 800 | 1,200 | ||

-

(1) Maximum working pressure

-

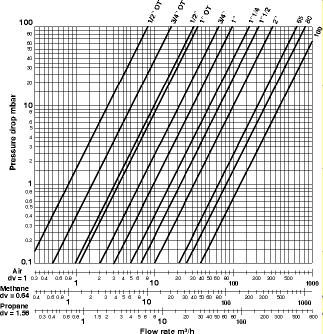

(2) Flow of methane with pressure drop of 0.5 mbar (5mmWG) and 1 mbar (10 mmWG).

-

100 mbar = 10 kPa = 1,000 mm.WG

PRESSURE DROP GNC

FEATURES OF GAS SOLENOID VALVES

|

Model |

Operation |

Advantages |

Disadvatages |

| Normally closed GNC |

|

|

|